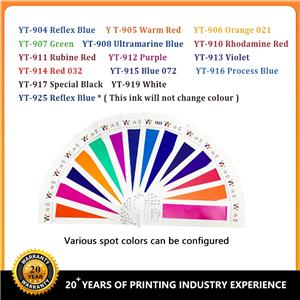

Spot Color Ink Mixing Skills

In offset printing, spot colors are used more often. Spot color inks are generally formulated by ink factories in accordance with certain standards. Even so, the spot color ink will have a difference between the printed hue and the color sample when it is printed on the machine. Here, take the red ink as an example to introduce the mixing techniques of spot color ink.

For a certain big red, in the CIEL*a*b* color space, L*=40.80, a*=59.80, b*=42.11. From this, we roughly know its position in the color space. The base ink that needs to be selected to mix the color is mainly red, and the color ink is deep red, golden red, black and thinner.

In contrast measurement, when one of ΔL*, Δa*, and Δb* is close to Z in the tristimulus value or greater than or equal to Z, the color difference will be more obvious when the color is observed with the naked eye. Therefore, L* is a very critical chromaticity index, which determines the main position of the color in the CIEL*a*b* color space.

If ΔL*>0, and the value of ΔL* is large, the color is brighter, and the ink layer appears thin from the perspective of printing; from the ink composition, the proportion of dark red ink in the ink is less. In this regard, two methods can be used to adjust, one is to increase the ink layer thickness by increasing the printing viscosity of the ink and reducing the printing speed; the other is to increase the ratio of deep red ink, and a very small amount of purple ink or Black ink can be used to adjust, yellow shade can be adjusted with gold red ink.

If ΔL*<0 is large, it means that the color is too dark. And when the absolute value of ΔL* and the color in the ink adjust the brightness, it will have some influence on the saturation of the color. Therefore, while adjusting the brightness, you can slightly add a little gold and red ink for fine adjustment, but it will not cause too much influence on the red cabinet and the yellow cabinet in the color. Of course, you cannot adjust the hue alone. When adjusting the yellow phase in the red ink, you can use orange ink or golden red ink instead of yellow ink for fine adjustment.

- Security Ink

- UV Invisible Ink

- Watermark Ink

- Optical Variable Ink

- Magnetic Ink

- Water Sensitive Ink

- Photochromic Ink

- Temperature Sensitive Ink

- Infrared Ink

- UV Fluorescent Ink

- Glow In The Dark Ink

- Glass Ink

- Mirror Ink

- Conductive Ink

- Scratch Off Ink

- Laser Ink

- Printing Chemical

- Plate Cleaner

- Spray Powder

- Hot Melt Adhesive

- Jelly Glue

- Gun Solution

- Fountain Solution

- Quick Drier Plus

- Printing Materials

- Dampening Sleeves

- Cutting Stick

- Creasing Matrix

- Double Wire

- Ink Duct Foil

- Underpacking Paper

- Underpacking foil

- Sponge

- Pantone Color Chart

- Ink Knife