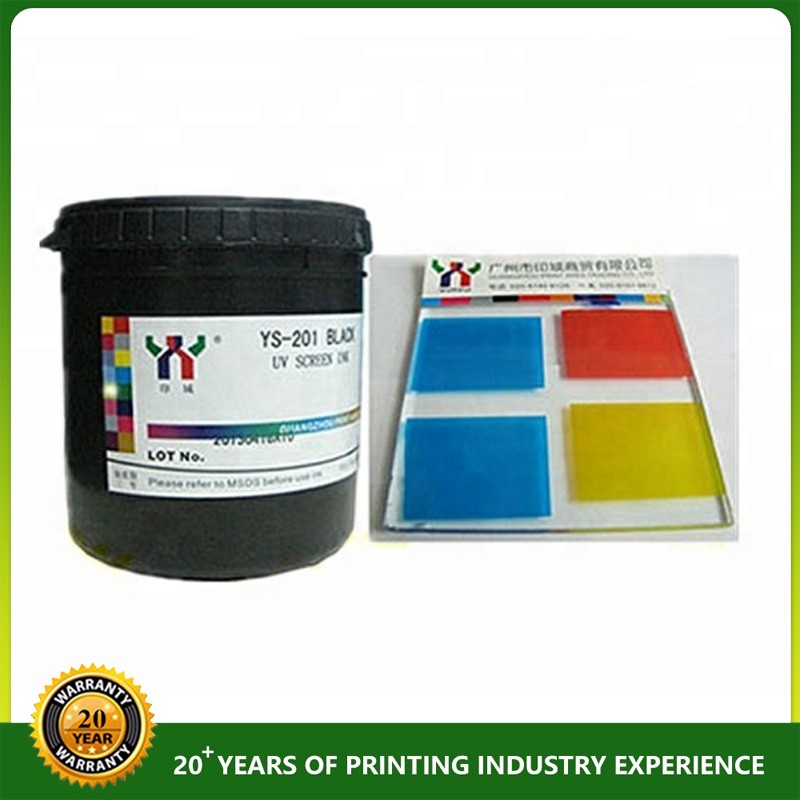

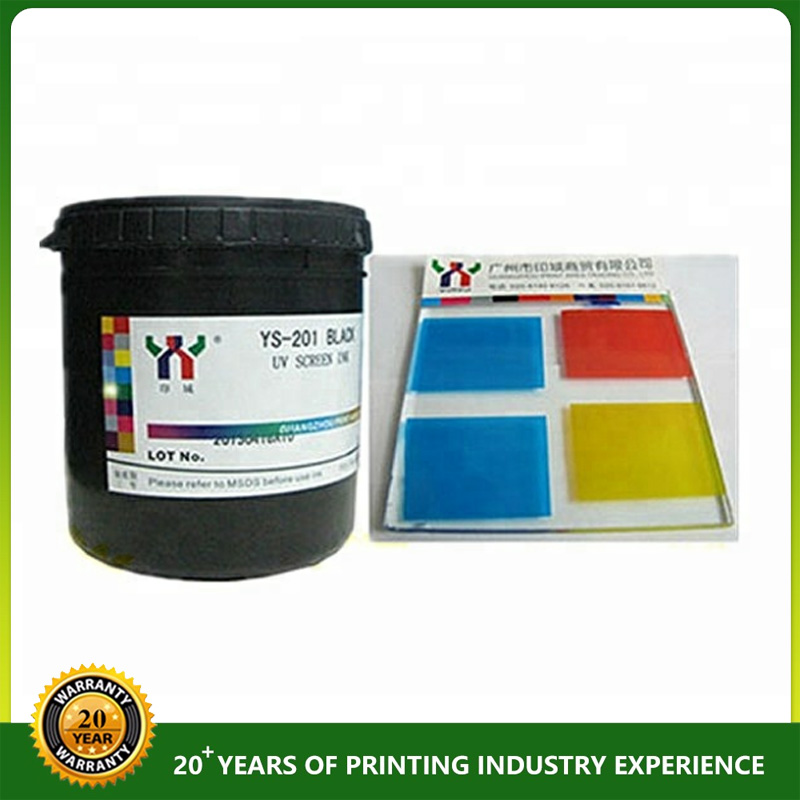

CMYK Ink Glass Bottle Ink For Screen Printing

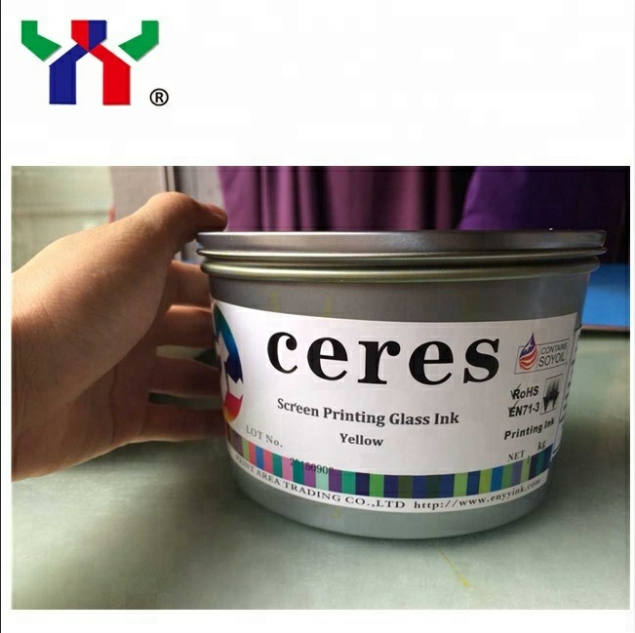

- Ceres

- Guangdong ,China

- 3-5 working days

- 50 ton per one month

Screen printing glass ink is used for ordinary glass, toughened glass, reinforced PC, pet, PMMA, ceramics, etc.It has excellent adhesion to the glass after drying.

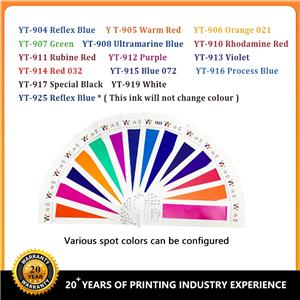

Screen printing glass ink has UV drying and ordinary drying two types.In addition to the common CMYK four colors, in recent years we have also developed gold, white, green gold and other new colors.

Please let us know the substrate before purchasing. We can provide free curing agent for customers to use with glass ink.

CMYK Ink Glass Bottle Ink For Screen Printing

How to use

1. Glass ink must be used together with curing agent, and the dosage of curing agent is 10-15%.

2. Oil and dust on the surface of substrate must be removed before printing.

3. For multi-layer printing, the bottom layer and middle layer need to be baked at 80 ℃ for 15 minutes until the surface is dry, and the last layer needs 150 ℃ for 30 minutes to ensure that the ink is completely dry.

4. After adding curing agent at room temperature of 25 ℃, the ink can be used for less than 6 hours.

5. Mesh plate cleaning: screen ink cleaner

Drying conditions:

Baking conditions:150 ℃ for 30 minutes

Package specification:

1kg/can

Storage conditions:

Keep away from fire source, store in cool and dry place, avoid direct sunlight; shelf life is one year.