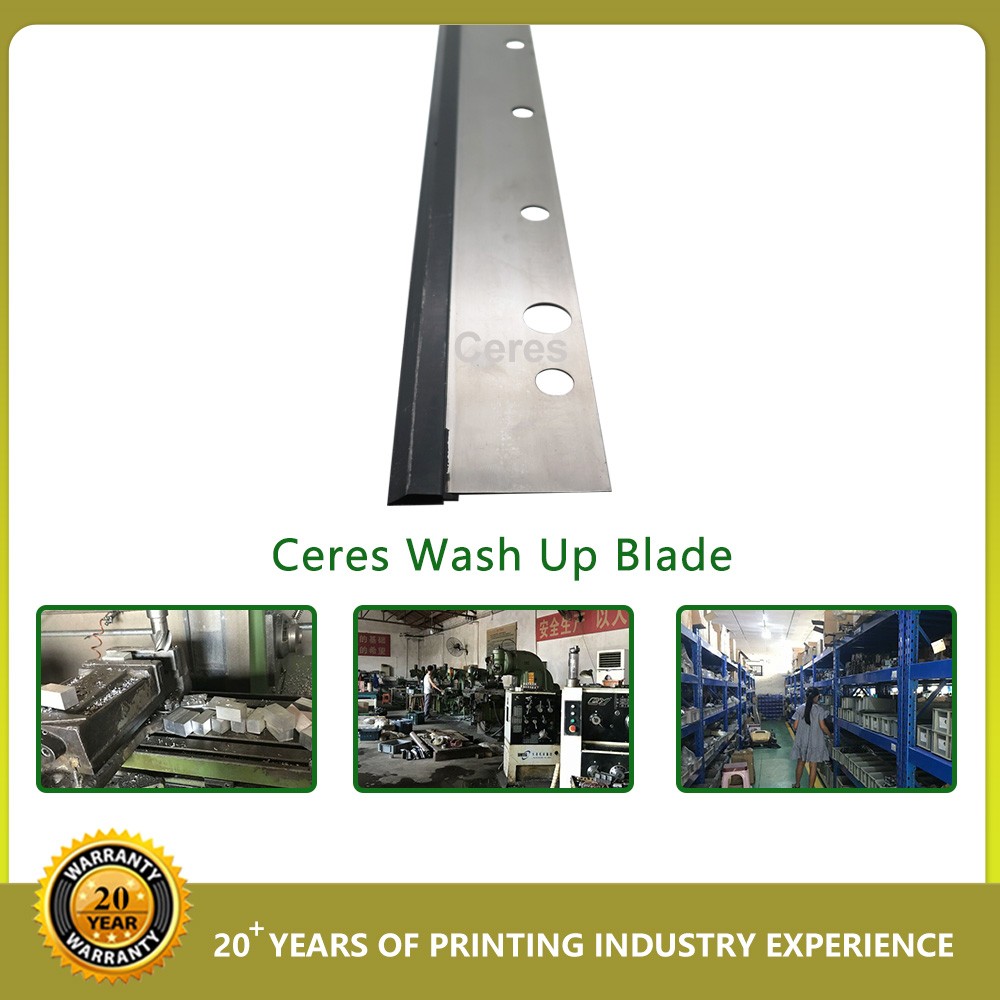

GTO46 And GTO52 Wash Up Blade

- Ceres

- Guangdong ,China

- 5-7 working dyas after payment is confirmed

- 20000pcs per one month

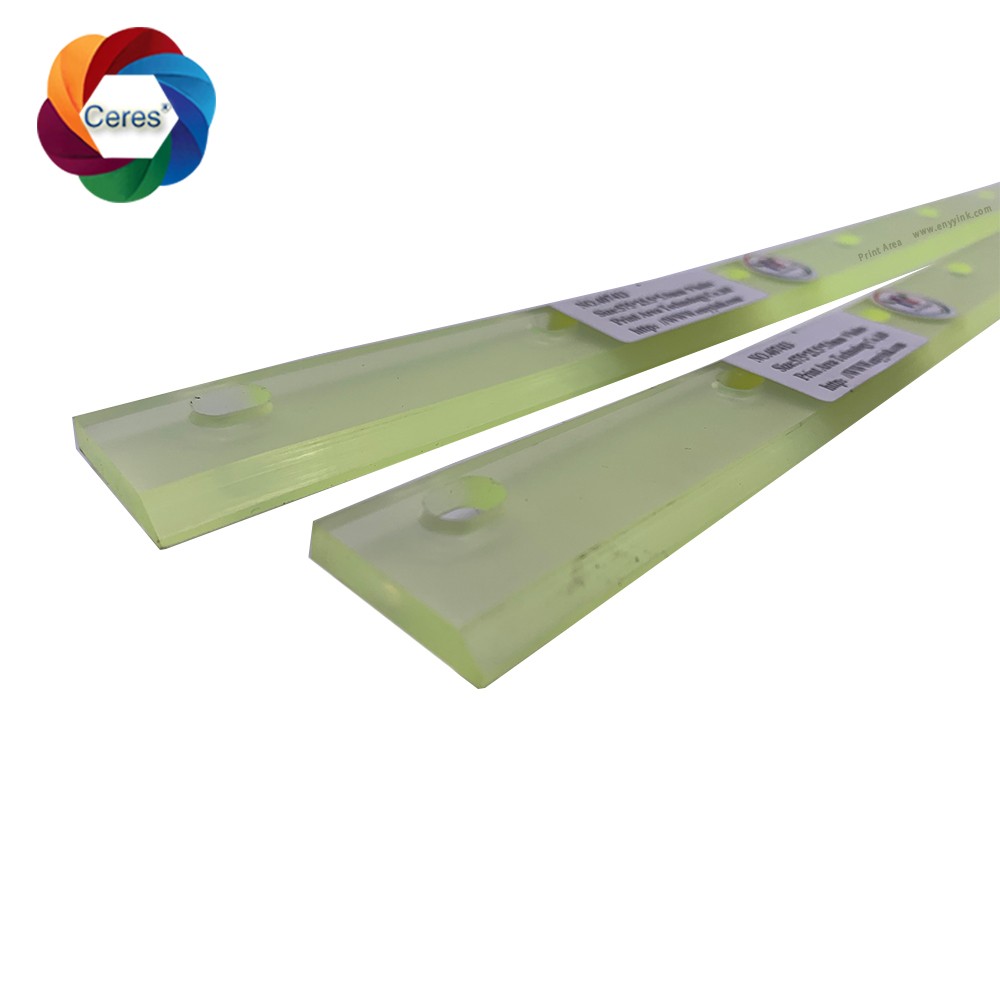

Wash up blade is used to remove excess ink on the surface of the printing press cylinder. In each printing process, removing the ink in the unpatterned area is a key point.

Before choosing wash up blade , you must understand the following:

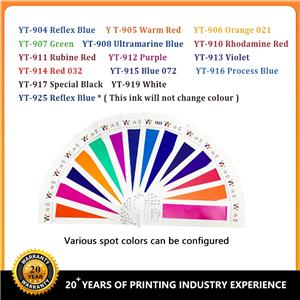

1. Types of printing: offset printing , gravure printing , flexo printing

2. Printing substrate: paper, plastic film, aluminum foil, etc.

3. Ink characteristics: solubility, water-based, coating adhesion

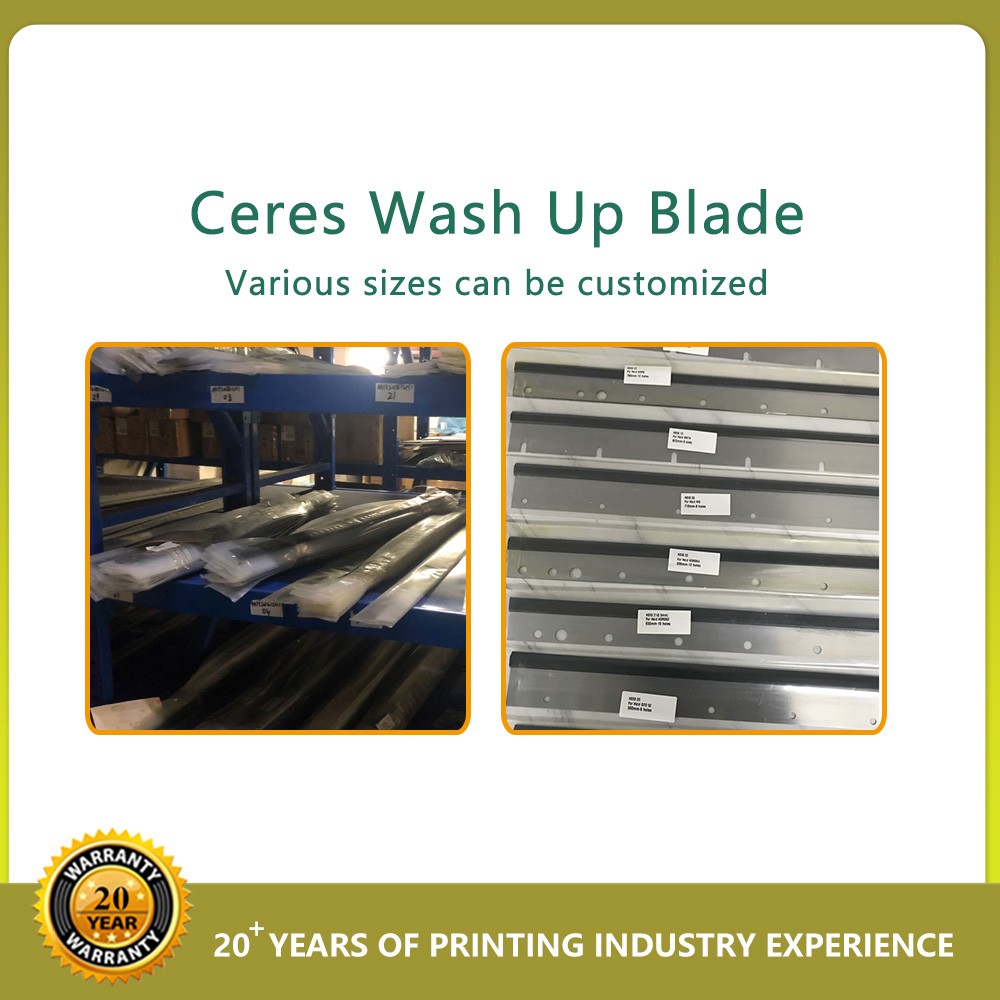

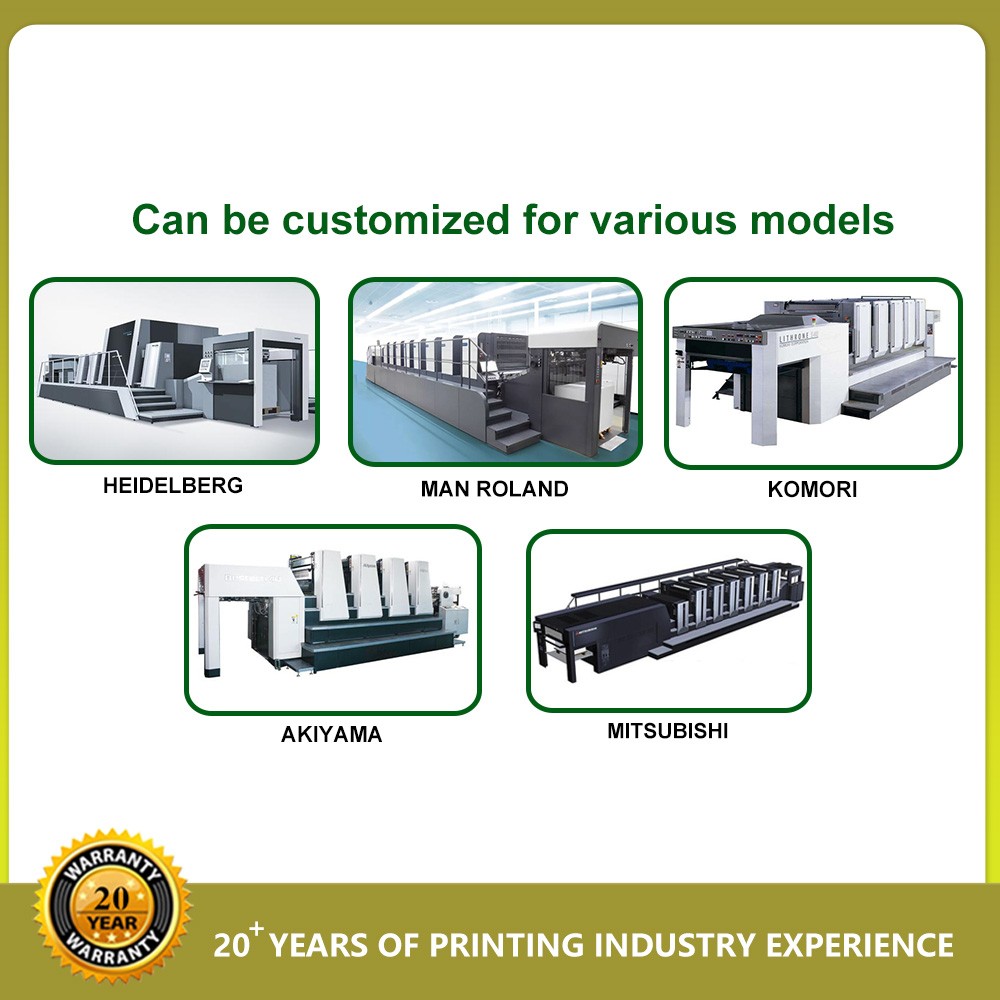

Applicable models: Komori, Heidelberg, Mitsubishi, KBA, Akiyama, Shinohara, Ryobi and so on

GTO46 And GTO52 Wash Up Blade

Models:

Advantages:

1. Quality guaranteed

2. Competitive factory price

3. Fast delivery, 4-7 working days to US/UK/AU

4. Keep a large stock of goods, which can be shipped in 24-48 hours after payment confirmed

5. Customized service and processing production service available

How to apply the wash up blade correctly

1.When opening the wash upblade box and pulling it out, please hold the blade to prevent it from being scratched by the blade, and check the cleaning wash up blade.

2.Test the pressure of the ink scraper: the pressure can be controlled and measured. The pressure should be adjusted to a minimum to reduce wear.

3.The wash up blade must be clamped in the standard tool holder, and there should be no residual ink block between the knife lining and the knife rest, so as to ensure the perpendicularity of the blade after clamping.

4.The blade side must face upward. The installation angle is 55-65.

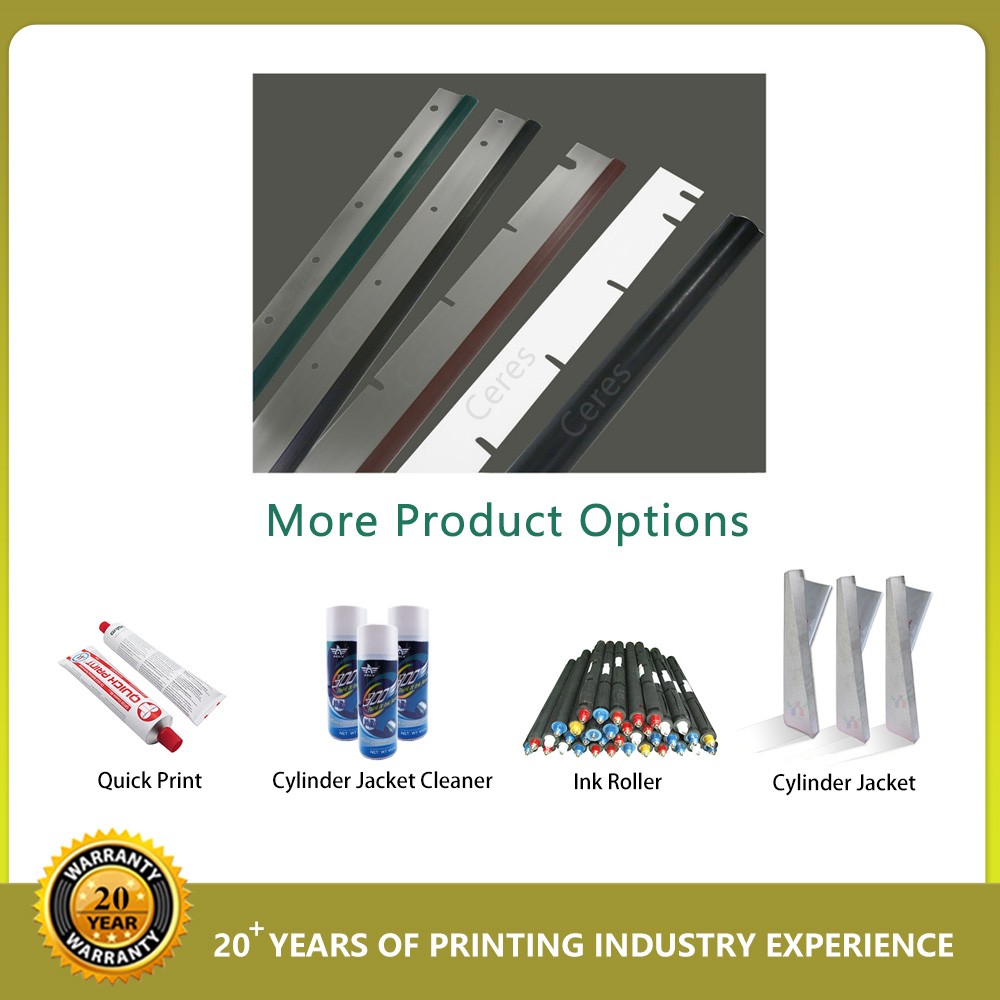

Related products