-

2021 Canton Fair Printing Exhibition

03-03-2021 -

Ceres UV Flexo Ink solves storage and shelf life issues

Narrow web flexo printing, gold and silver ink products that have always been troubled, shelf life has always been a problem Ceres ink team, after long-term research and development efforts Finally breaking through the limitation of shelf life, the latest research and development results of Ceres UV Flexo ink can achieve a shelf life of 1 year

14-05-2022 -

Influence of LED-UV Curing Technology on Printing UV LED Inks

LED-UV light source 1. Advantages (1) The energy consumption is lower, the effective luminous efficiency is high, and the energy consumption can be reduced by 70% to 80%.

06-07-2022 -

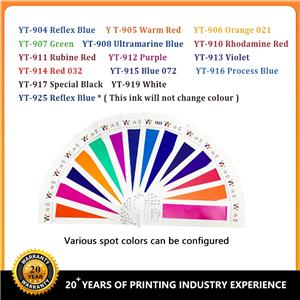

Ceres UV flexographic printing ink

Ceres UV flexo ink mainly has the following kinds of UV flexo printing inks to choose from. Fast curing speed, not easy to paste, high definition, bright colors, bright and wear-resistant, good chemical stability, suitable for color fine product printing.

10-07-2022 -

New trends in the global can industry and ink development

The impact of inks on the can industry The metal surface is smooth, the texture is hard, and it does not absorb ink, so it is usually printed with heat-curable ink. Due to the different printing methods and printing materials, the composition of the ink used in the three-piece can and the two-piece can is also different. The ink used in the three-piece can (ie tinplate ink) is mainly composed of alkyd resin, phenolic resin and melamine resin. The two-piece can is printed on a round and curved surface, and the printing pressure is small, so the requirements for the performance of the ink are more stringent. The base material of the ink for two-piece cans is mainly fatty acid modified alkyd resin and polyester resin.

06-07-2022 -

2 minutes to quickly understand "flexographic printing"

Flexographic printing can use water-based ink, UV ink, solvent based ink, so it can adapt to different materials, environmental requirements.

24-11-2022