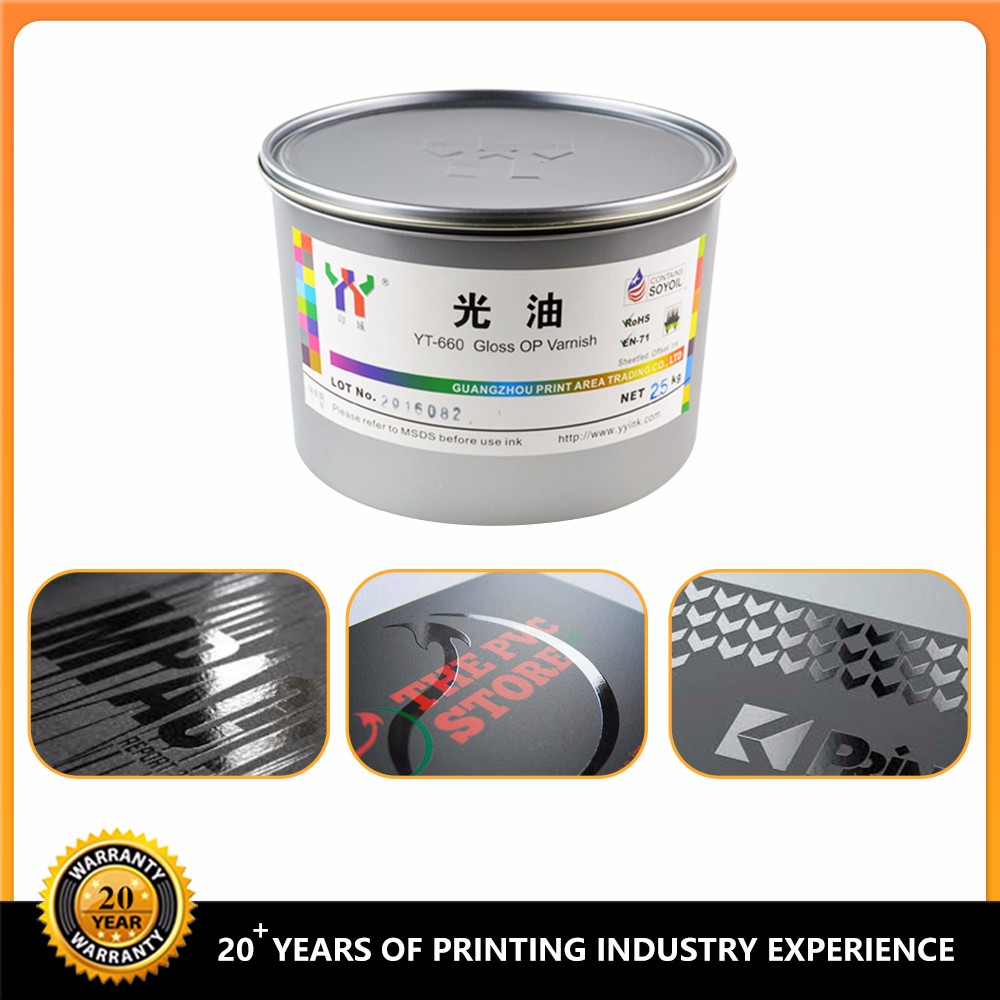

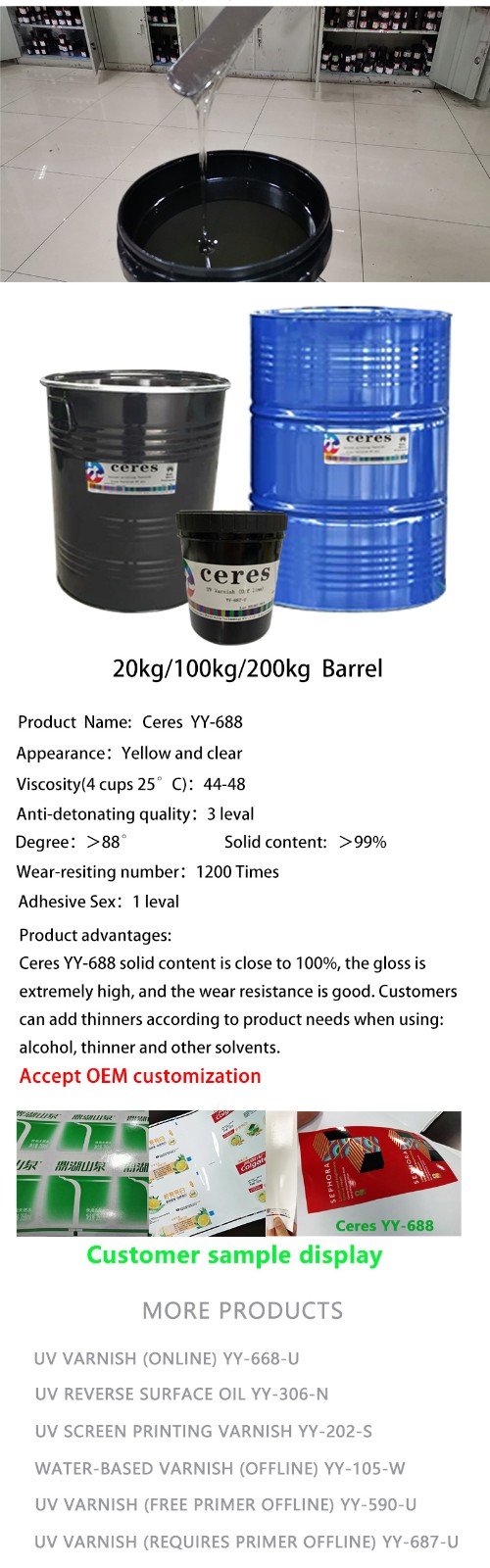

Ceres High Gloss OP Varnish for Package

- Ceres

- Guangdong ,China

- 3-5 Working days after payment is confirmed

- 50 ton per one menth

Varnish is a kind of synthetic resin. Now it usually refers to the transparent varnish on the surface, which is made of base materials and additives, without any pigment. After the film is formed, the oil will shine bright, commonly known as OP varnish.

OP varnish has the following characteristics

1. The layer has high transparency and is not easy to turn yellow.

2. The film has a certain degree of wear resistance.

3. It has certain flexibility.

4. The film has better environmental resistance.

5. It has certain adhesion to the surface of printed matter.

6. Good leveling and smooth film surface.

7. Wide post-press processing adaptability.

Ceres High Gloss OP Varnish for Package

Introduction :

OP varnish is used in all offset presses.

Characteristic:

1. High layer transparency and no yellowing. To obtain an excellent glazing effect for printed matter, it depends on the formation of a colorless and transparent film on the surface of the printed sheet, and the graphics and text do not change color after drying. And it should not be discolored or yellowed due to sun exposure or long time of use.

2. The film has a certain degree of wear resistance. Some glazing prints require certain abrasion resistance and scratch resistance after glazing. Because of the use of high-speed box making machines, cardboard box packaging machine devices, and book jacketing and other assembly line production processes, the surface of the printed matter is rubbed, so it must have wear resistance.

3. It has certain flexibility. The bright film formed by any varnish on the surface of the printed matter must maintain good elasticity to be compatible with the flexibility of the paper or cardboard, and will not be damaged or cracked or peeled off.

4. The film has better environmental resistance. Some printed matter after glazing is used to make various packaging cartons. In order to protect the packaged products, the glazing film must have good environmental resistance. For example: the packaging of food, cigarettes, cosmetics, clothing and other commodities must have moisture and mildew resistance. In addition, the chemical properties of the dried film should be stable. The performance cannot be changed due to contact with chemical substances such as weak acids or bases in the environment.

5. It has certain adhesion to the surface of printed matter. As printed matter is affected by the integral density value of the ink layer on the surface, the surface stickiness is greatly reduced. In order to prevent the film from cracking and peeling during use after drying, the film is required to have strong adhesion, and it is used for ink and ink adjustment. The auxiliary materials have a certain degree of adhesion.

6. Good leveling and smooth film surface. There are a wide variety of printed materials, coupled with the influence of printed graphics, the surface absorbency, smoothness, wettability, etc. are very different. In order to make the glazing paint can form a smooth film on different product surfaces, varnishing is required Good leveling and smooth film surface after film formation.

Note:

Do not add thinner casually, which will affect the color change and gloss of the varnish.

It is normal for the varnish to appear less milky when this product is turned on. If the machine is stopped for a long time, it needs to be cleaned to avoid drying on the ink roller.

Our Company