The difference between ordinary offset printing ink and UV offset printing ink

The difference between ordinary offset printing ink and UV offset printing ink

At present, offset printing technology includes both ordinary offset printing and UV offset printing. With the rapid development of offset printing technology, if we do not have a timely and in-depth understanding of new materials and new processes, we may encounter many problems in the printing process. This paper will introduce the product characteristics, differences in use and future development trend of ordinary offset ink and UV offset ink in detail, hoping to discuss with peers.

Difference between ordinary offset printing ink and UV offset printing ink

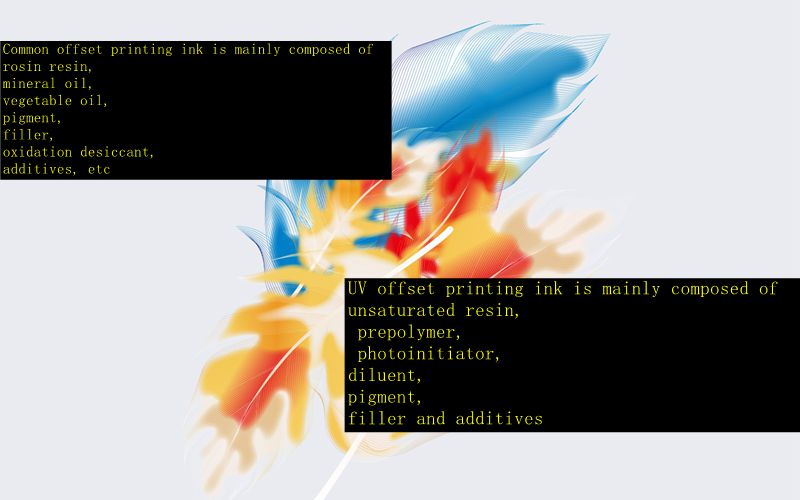

Ordinary offset printing ink is mainly composed of rosin resin, mineral oil, vegetable oil, pigment, filler, oxidation desiccant and additives. Its drying process depends on the combination of surface oxidation conjunctiva, internal binder penetration of ink layer and solvent volatilization. This drying process is not sensitive to temperature and can adapt to a wide temperature range. At the same time, the daily lighting source has little effect on the drying process of ordinary offset printing ink, but in the process of transportation and use of ordinary offset printing ink, it is necessary to avoid prolonged contact with oxygen.

UV offset printing ink is mainly composed of unsaturated resin, prepolymer, photoinitiator, diluent, pigment, filler and additives. Its curing process is that under the irradiation of ultraviolet light, the photoinitiator absorbs the radiation energy of ultraviolet light and splits into free radicals, which initiates the polymerization, cross-linking and grafting reaction of prepolymer, and solidifies into three-dimensional network polymer in a short time to form a hardened film. In this process, UV intensity determines the curing degree of UV offset ink. In addition, temperature also has a great impact on the stability of chemical components in UV offset ink. Therefore, UV offset ink needs to be transported, stored and used in a dark, normal or low temperature environment.

The following will introduce some differences between ordinary offset ink and UV offset ink in the printing process.

1. Differences applicable to offset press

The offset press suitable for ordinary offset ink belongs to ordinary offset press, which is also often called standard offset press. At present, the manufacturing technology of ordinary offset press has been quite mature, such as Heidelberg, Manroland Ordinary offset printing machines produced by well-known manufacturers such as gaobao, Komori and Mitsubishi have been widely used in China. These offset printing machines are basically equipped with infrared or hot air drying devices and powder spraying devices, which can ensure the drying of ordinary offset printing ink and prevent dirt.

There are roughly two kinds of offset presses suitable for UV offset ink.

(1) UV special offset press, that is, there is a UV lamp tube or a module that can install a UV lamp tube behind each color deck, and a UV curing device is installed at the paper receiving place.

(2) UV offset press modified from ordinary offset press. This kind of UV offset press replaces the cots of ordinary offset press with accessories suitable for UV offset printing, and usually adds three groups of UV lamps as curing devices in the paper receiving part. However, because there is no UV lamp between the color groups of this kind of offset press, the failure of poor curing often occurs when the ink layer is thick, and the installation of UV lamp in the paper receiving part will have the possibility of UV leakage, which is not safe. Therefore, enterprises using this kind of UV offset press need to pay special attention to its curing ability when selecting the type of UV offset ink.

In addition to the above offset presses, there is also an ordinary / UV dual-purpose offset press. Its rubber roller is suitable for the printing of two types of inks. The offset press is equipped with infrared, powder spraying and UV curing devices, but the disadvantage of this kind of equipment is that it has high requirements for the printability of UV offset ink, In particular, there will be poor printing effect at the initial stage of switching between ordinary offset ink and UV offset ink, which requires a long ink adaptation process. In addition, the service life of such offset press cots and other accessories is also relatively short.

Difference between printing color sequence

Of four-color offset printing ink- - The general color sequence is: black blue red yellow. UV offset printing breaks the limitation of ordinary offset printing ink in color sequence, and the color sequence can be changed at will. The reason is: firstly, in principle, UV curing device should be equipped behind each color group for UV printing (at least one group of curing device is required after two color groups), so there is no cross color and anti adhesion problem for the color that is cured quickly or basically; Secondly, considering the characteristics of UV offset printing, UV offset ink manufacturers uniformly control the viscosity of red, yellow, blue and black UV ink, and will not design different viscosity due to the special needs of printing products, but customers can reasonably add viscosity reducer or ink adjusting oil to adjust the ink viscosity in the actual use process. Therefore, the printing color sequence of UV offset printing can be set reasonably according to the needs.

3. Differences in matching of printing consumables

(1) Substrate

In countries with developed printing industry, the range of substrates involved in ordinary offset printing ink is relatively small, mainly focusing on absorbable substrates (paper) On; UV offset ink is used for printing on paper, all kinds of plastic sheets, gold and silver cardboard and other substrates.

In contrast, in China, due to the influence of equipment cost, ink cost, printing factories and printing habits, ordinary offset printing ink is widely used in the printing of absorbable paper substrates such as magazines, books and periodicals and bills, while UV offset printing ink is mainly used in the printing of non absorbable substrate materials such as gold and silver card paper and plastic sheet, and the intersection of the two is very small. Although this situation is in line with the development of domestic printing industry, it objectively hinders the cooperation between ordinary offset printing technology and UV offset printing technology.

(2) PS plate, cot, fountain solution and other auxiliary materials

Due to the strong chemical activity and high corrosiveness of UV offset printing ink, special printing consumables must be equipped during UV offset printing.

First of all, a PS plate suitable for UV offset printing needs to be equipped. Specifically, the traditional PS plate needs to be baked to strengthen the surface strength of the PS plate and improve the corrosion resistance.

Secondly, special UV cots or dual-purpose cots must be used. The reasonable choice of COTS has important influence on the transfer of ink and the reproducibility of printing. The hardness of different cots is different, the aging resistance is different, the service life is different, and the ink transfer ability and ink blending ability are different, and the printing effect is different.

Thirdly, the fountain solution used by ordinary offset ink and UV offset ink is also different. The performance parameters of fountain solution, such as pH value and surface tension, will directly affect the ink balance. The selection of appropriate fountain solution has an important impact on the control of printing quality and the use of PS plate, blanket and cot- In general, the pH value of fountain solution used for ordinary offset printing ink is controlled at 4.5 or 5.5, The pH value of the fountain solution used for UV offset printing ink is controlled at 4.5 or 5.0; The surface tension of the fountain solution used for UV offset printing shall be less than that of the ordinary fountain solution.

Finally, UV offset printing must also use special ink additives, additives, cleaning agents and so on.

In addition, it should be noted that UV offset printing ink and ordinary offset printing ink shall not be mixed, and different series of UV offset printing ink shall not be mixed. UV offset printing must use the auxiliary materials recommended by the manufacturer, and it is best to use the products of the same brand, because mixing and miscellaneous use may cause UV offset printing ink gelatinization and unpredictable loss.

4. Differences in process control

(1) The hardness of UV offset cots is relatively large, so greater printing pressure is required during printing. At the same time, during printing, the temperature between UV offset rollers is higher than that during ordinary offset printing. Therefore, it is best to always pass cooling water in UV offset rollers. For printers without water cooling device, it is necessary to avoid the impact of heat generated during long-term printing on the performance of UV offset ink. When using UV offset ink to print on non absorbent substrate, special attention should be paid to prevent static electricity.

(2) The amount of ink in the ink bucket. Compared with ordinary offset printing, UV offset printing should avoid adding too much ink in the ink bucket. It is best to add it in a small amount and many times, so as to avoid UV offset printing ink hardening in the ink bucket. (3) During UV offset printing, attention shall be paid to avoid the sunlight of surrounding windows. At the same time, special fluorescent lamps without UV rays shall be selected in the workshop.

(4) During the quality management of ordinary offset printing products, it is necessary to confirm the possible color deviation problems of ink color, dot and image definition on the paper before and after complete drying, drying performance and possible anti adhesion and stacking problems, and the matching problems of post press processing such as hot stamping, polishing, film covering and so on.

For the quality management of UV offset printing, we first need to confirm the curing problem of UV offset printing ink, that is, whether the lamp power of the printer can meet the curing requirements of UV offset printing ink. Secondly, it is necessary to confirm whether the UV offset ink has sufficient adhesion fastness on the substrate. If the adhesion fastness of UV offset ink in the printing process is poor, the printing products will be prone to problems such as ink drop and color explosion in post press processing. Thirdly, we also need to confirm the transparency, flexibility, color, gloss and other properties of the printing according to the specific design requirements of the printing.

5. Differences between environmental health and safety protection

Most of the components of ordinary offset printing ink are highly inert binder, mineral oil, vegetable oil, etc., and the drying process is relatively slow. Therefore, the chemical activity of the ink is small, and the direct infringement and corrosivity to human body are relatively weak. However, ordinary offset printing ink has the possibility of secondary pollution and damage to human health in the printing process, Therefore, it is necessary to classify the risk prompt according to the printing demand.

UV offset ink; It is composed of unsaturated resin, monomer and photoinitiator with high chemical activity. The curing process is a chemical reaction process. Therefore, if the UV offset ink before curing is in direct contact with the human body, it will cause strong stimulation and corrosion to the human skin and respiratory tract. In particular, some UV offset ink manufacturers will add carcinogenic photoinitiators such as benzophenone and itx to the UV offset ink in order to reduce the cost of UV offset ink. If the printing operators using these UV offset ink do not have protection for a long time, it is equivalent to chronic poisoning. However, after the UV offset printing ink is printed into the finished product, due to the full reaction of the chemical components in the ink, there will only be a very small amount of toxic substance residues and little possibility of chemical substance migration in the print, so the safety is greatly improved. Therefore, the safety protection of UV offset printing is mainly reflected in the links before and during printing, and there will be no secondary pollution after printing.

Future development of ordinary offset printing ink and UV offset printing ink

For ordinary offset printing inks, in the future, we should focus on the development of high color, wide color gamut, using renewable vegetable oils such as soybean oil and rice bran oil to replace mineral oil, and ordinary offset printing inks suitable for short version printing.

For UV offset printing ink, reducing ink price and expanding the scope of use are the focus of future research and development. In addition, research and development of UV offset printing ink with special effects, such as microcapsule fragrance UV ink, UV ink that can achieve on-line cold hot stamping effect, UV offset printing ink that can produce similar concave convex printing effect, etc.

Whether for ordinary offset printing ink or UV offset printing ink, it will become an obvious development trend to provide products with more safety, environmental protection and more distinctive characteristics.