what is uv offset ink

What are the characteristics of UV offset ink? What is the scope of use?

UV offset printing ink is composed of connecting material, active diluent, photoinitiator, pigment and additives. Using the ultraviolet radiation energy, the liquid chemicals are quickly crosslinked and solidified into ink film. UV offset printing ink has the commonness of ordinary offset printing ink, such as fluidity, dispersion, anti emulsification, viscosity, low flying ink, good transfer, dryness and post press processability.

At the same time, UV offset printing ink has its own characteristics, mainly in the following aspects:

Fast curing speed. Under the irradiation of ultraviolet light, it can be cured in a few seconds. In packaging and printing, it is often necessary to print a large area on the spot and require high density. Therefore, the amount of ink has to be increased. At this time, the problem of drying becomes very important.

Because the UV ink does not contain solvent, the thickness of the cured ink layer is basically the same as that of the printing ink layer. The printing area of the UV ink per unit weight is 30% - 50% larger than that of the ordinary ink. There is no penetration when curing, and it can be printed on non absorbent substrate materials, such as card printing, which is a field that ordinary offset ink can't get involved in.

Because UV ink does not need powder spraying during printing, the printing environment is well improved, the trouble caused by powder spraying to post press processing, such as the impact on glazing and film coating effect, can be avoided, and wiring processing can be carried out.

UV ink is bright in color. Its scratch resistance, wear resistance, acid and alkali resistance are better than ordinary ink, and its stability is very strong.

Scope of use:

Uvu: white cardboard, gold and silver cardboard, pet coated cardboard, laser cardboard, metal aluminum foil paper, PVC substrate, etc.

Uvus: synthetic paper, self-adhesive label, PVC series, PC, pet, PE, treated PP and other non absorbent substrates.

After printing, it is irradiated by UV lamp and solidified instantly. It can be processed immediately without back printing or sticking dirty; Good adhesion to most non absorbent substrates; High color intensity, high fullness, good ink transmission, providing good dot definition;

- Security Ink

- UV Invisible Ink

- Watermark Ink

- Optical Variable Ink

- Magnetic Ink

- Water Sensitive Ink

- Photochromic Ink

- Temperature Sensitive Ink

- Infrared Ink

- UV Fluorescent Ink

- Glow In The Dark Ink

- Glass Ink

- Mirror Ink

- Conductive Ink

- Scratch Off Ink

- Laser Ink

- Printing Chemical

- Plate Cleaner

- Spray Powder

- Hot Melt Adhesive

- Jelly Glue

- Gun Solution

- Fountain Solution

- Quick Drier Plus

- Printing Materials

- Dampening Sleeves

- Cutting Stick

- Creasing Matrix

- Double Wire

- Ink Duct Foil

- Underpacking Paper

- Underpacking foil

- Sponge

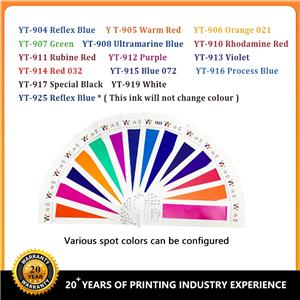

- Pantone Color Chart

- Ink Knife