label printing machine

-

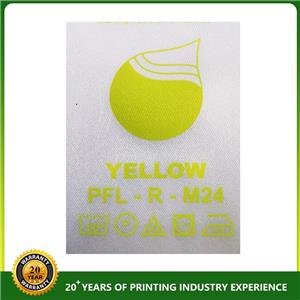

Ceres Flexographic printing ink for washing cloth label

No odor, strong ink coloring power, smooth and flat ink surface, good ink on flexo, and moderate drying speed. Prints are washable without fading, and can withstand strong water washing, stone mill washing, enzyme washing, etc

Email Details -

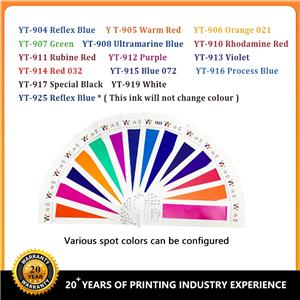

Flexo Fabric Rotary Label Printing ink For Textile Cloth Ribbons

How to use this flexo label ink : Please mix the ink thoroughly before use; Please use special diluent, adjust the dilution within 3-10%; In order to improve the adhesion, 3-10% of special hardener can be added. After adding, it needs to be fully stirred. The ink can be used for 4 hours after being mixed. So please be careful not to blend too much at one time), you need to fully dry after printing; The conventional drying methods are: hot air blowing and drying. After the printed trademark tape is fixed in a constant temperature oven, it can achieve extremely high color fastness. Ribbons and woven tapes are dried in a 100 degree oven for 4 hours (120 degrees and 2 hours), nylon, cotton tape, and polyester are dried in an 80-90 degree oven for 4-8 hours. The effect of dry cleaning. The drying, adhesion and ink film characteristics of the ink are related to the time of the drying temperature.

Email Details